Typically used as the first part of a profile curing system, microwave hot air ovens from KRR apply heating power using targeted high temperature air streams and a unique UHF spread pattern for the highest heat delivery in the industry.

Features:

• Air speeds to 4000 ft/min (20m/s) and 650°C.

• Self-guiding under air stream that supports the profile for conveyor-less transport.

• Live air-speed monitoring for diagnostic purposes.

• Profile channel temperature control is standard + or – 2 degrees C for each oven zone. Set-point ramping and cascade PID included.

• Master air speed is adjustable for 50% to 100% of the specified air speed of each section.

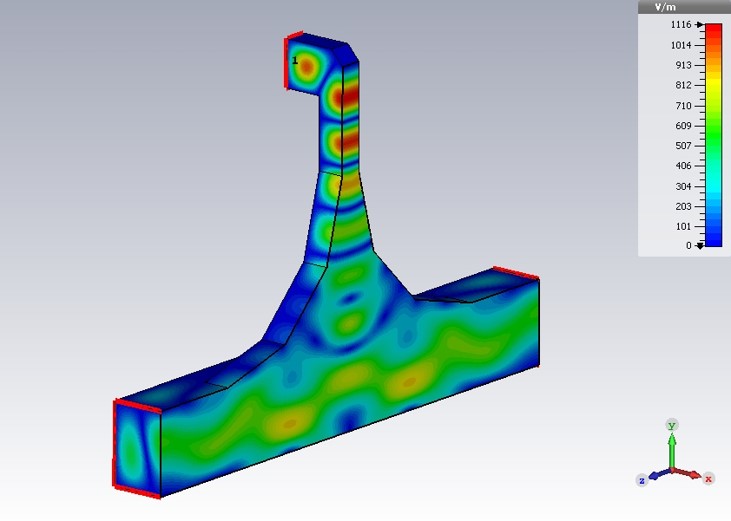

• UHF power to 24kW available with circulators and tuning to minimize reflected power for long magnetron life.

• Wave traps to reflect fugitive microwaves reducing lost power.

• Standard 6 kW magnetrons (YJ1600) and power spreading waveguide to avoid profile blisters.

• Pneumatically operated lids by 1 lever handle per section.

• Conveyor transport of unsupported profiles and rollers pockets for supported sections are both provided standard.

• Profile entry conveyor retractable with swing arm option available.

• Two profile break safety alarms (entry and exit) are provided as a smart alarm system connected to your extruders and pullers.

• CO2 fire suppression nozzles provided every 3m. Fire control sensors and systems available upon request.

Auxiliary Equipment

• Water wash tank for profile cooling.