The cryogenic profile cooling chamber offers a solution to plastic extrusion where surface defects are formed from traditional calibrator block and water cooling. Using liquid Nitrogen, the unit can cool high velocity air to -100 °F (-73 °C). Optional versions can nozzle inject the air to one or both ends of the cavity depending on the length of the unit.

Building on past experience, KRR Inc. now provides solutions to exhaust channel icing as well as internal injection nozzle icing.

For more profile control, an extended bonnet manual liquid Nitrogen valving is also provided at the entrance of the unit for use directly on the profile as it exits the extrusion die.

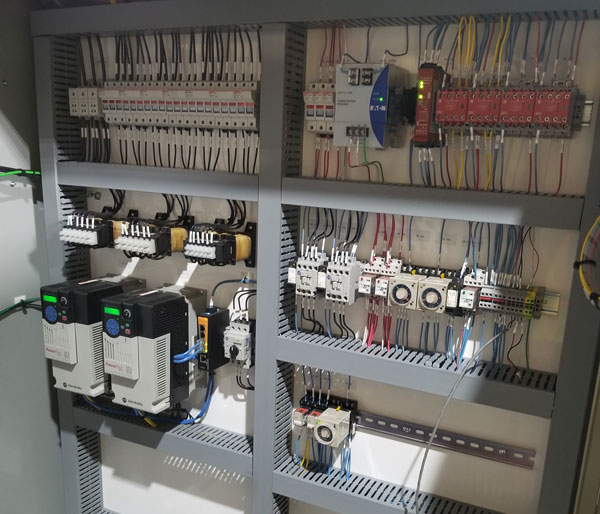

Since Nitrogen is an asphyxiant, a full safety sequence for recirculation and exhaust air proving is provided. The shutdown purge timing system mirrors the safety systems provided for gas fired EPDM extrusion profile curing systems also provided by KRR Inc. (pictured below).

.jpg)